|

|

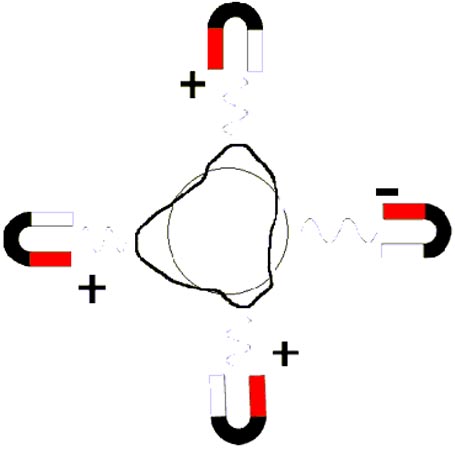

Basic idea behind skeleton expansion is to transform curves to some 3D object and then deform this object. The usable 3D object can be a cylinder with circular or elliptic cut and it is called fibre in this context. Fibres are deformed by deformation functions. There are three categories of deformation functions and each category is defined to change another feature of fibre. This categories are contour functions, magnetic functions and correction functions. Contour functions are aimed to bend fibres without change of its cut. Magnetic functions are identified to change cut of fibre. Idea of magnetic function is as follows. Fibre is made from limitless elastic and magnetic material and its proportions can be changed by magnets. Several magnets with different magnetism are placed around fibre's cut (see Figure 5) and this magnets change cut of fibre. Those rings of magnets are placed along whole fibre and they change cut of fibre in all locations. Magnetic function is designed to change basic shape of fibre. Correction functions are aimed to make deformed fibre looking better (see figure 4). Correction functions cooperate with magnetic functions and they roughen surface of deformed fibre. They are not intended to be used for expressive change of fibre shape but to change its surface. Proper use of deformation functions is highly recommended.

|

Technique of design of deformation functions enables us to have either flat or solid fibres (see Figure 6 and Figure 7). It is left on author's consideration, whether he whish to have flat fibres or not. So called materials are also created and mapped during process of skeleton development.

Material determines final surface adjustment and it contains texture mapping, light emission, transparency, etc. In addition, two types of fibres are distinguished in plant model. They are so called wooden fibres and leaf fibres. In other words, you can use another sets of deformation functions, materials or prescribe flatness or roundness for each type of fibre separately. That enables us to design different looking parts of plant that have another features.

|

Design of deformation functions has also influence on quality of future plant model. There exists a proportion between number of used magnetic funtion and quality of model. More magnetic functions in ring means better quality but those models are also more memory extensive. Consumption of memory is still a big problem because models are either too big to be visualised as fast as we wish, or they are not looking as good.